WHAT IS FAST VTA ADJUSTMENT?

Reed 3P, as well as it’s predecessor Reed 2P, is equipped with Fast VTA (Vertical Tracking Angle) adjustment feature. Of course, Reed’s VTA can be changed using fine VTA adjustment knob on the top of the tonearm base, so one may ask — why is that extra “Fast VTA adjustment” handle is needed? The idea behind Fast VTA adjustment is that human senses (in our case – ears) can determine peak performance only if something changes fast. If changes occur relatively slowly, they adapt to “current” situation and it’s not easy to tell the difference between the starting situation and the ending one.

Fast VTA handle allows changing VTA quickly, so that listener could be able to tell if he sensed the best sound in the given VTA range. For example, with 9.5″ tonearm and using Fast VTA handle you can quickly change VTA by 0,95 degrees. In comparison, one full revolution of fine VTA knob will change VTA only for 0,36 degrees, i.e. it will take more than 2.5 revs to get the effect of single Fast VTA handle movement.

So for people, who adjust VTA based on their ear, Fast VTA adjustment handle will help to do that easier and faster.

MAGNETIC TONEARM PROTOTYPE – REED MAG

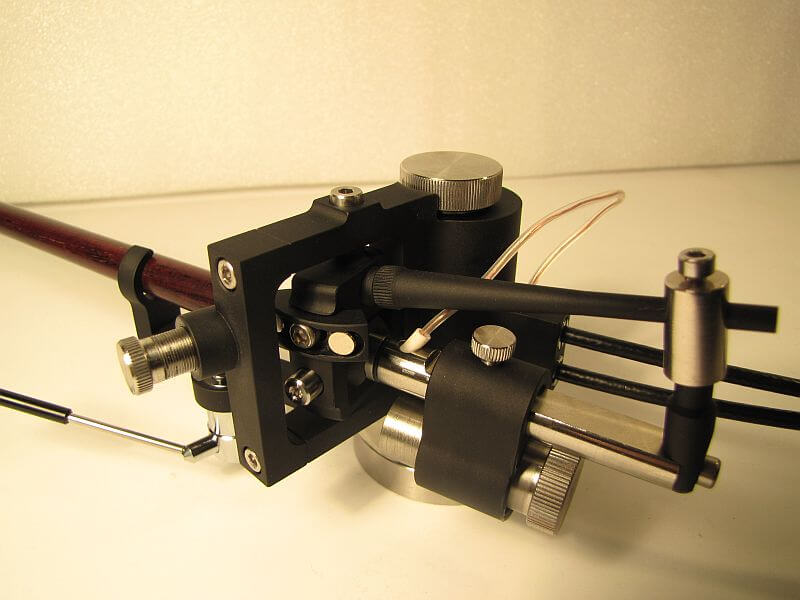

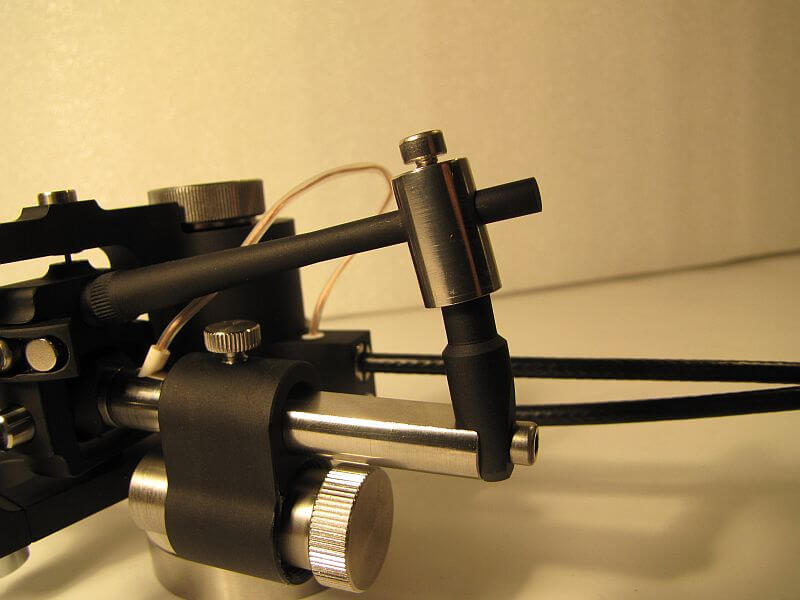

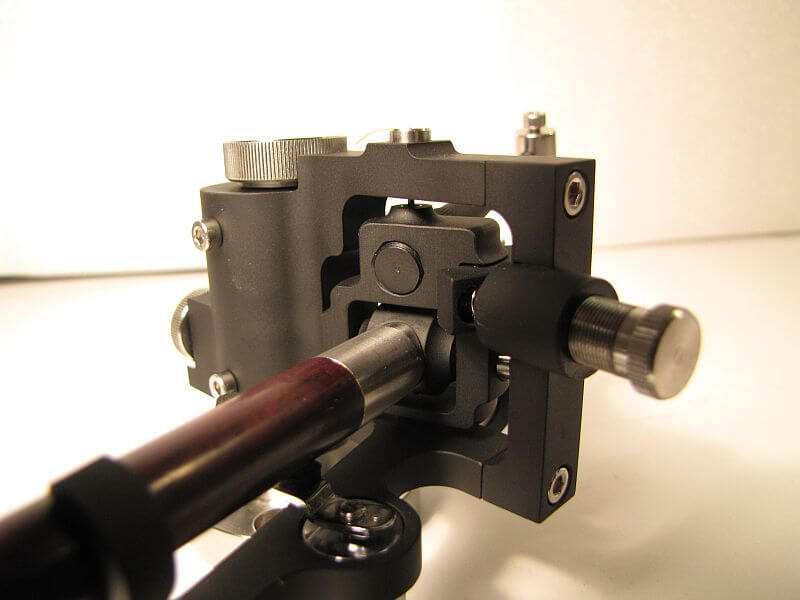

Probably it’s time to talk about what was keeping us busy for last year; actually we were designing, building and testing our newest creation – “magnetic” tonearm prototype, called Reed Mag.

This model features magnetic antiskating technology which eliminates the possible noises brought up by the traditional mechanical antiskating. Moreover, it has possibility to change a character of antiskating force (i.e. force can be different or constant depending on the cartridge’s distance from the center of the disk).

Also we introduced the dynamic magnetic damper to absorb tonearm’s vertical motion. The damping helps out a lot if you are listening to LPs which are slightly warped (if not stored properly, all vinyls may become warped sooner or later).

Damper’s operation is based on Lenz’s Law, when a neodymium magnet (located at enough distance from the wires to prevent various interferences) moves in a silver-plated pure copper tube. The damping coefficient is set to 3:1, which means that the tonearm’s free oscillation stopping time is three times bigger compared to the damped one. The damping force depends on the tonearms motion acceleration. With currently available cartridges, the damping coefficient exceeding 5:1 can result in sound distortion.

Reed Mag will also retain compatibility with our laser-based azimuth/VTA adjustment system. Despite it is currently only a prototype, it has bright prospects to become a member of our Reed family and set a parallel trend in our antiskating techniques.

Below are some lab pictures of Reed Mag.

WOOD VS. THE REST: TESTING ARMTUBE MATERIAL

There are lots of talks in the industry on the best armtube material, whether wood is better than Aluminum, or maybe Carbon fiber is the perfect material and so on.

To find out who’s right and which material is perfect for hi-fi tonearm armtube, we decided to conduct a little research.

We hope that results of our investigation will help you understand armtube material impact to the tonearm’s sound and help choosing tonearm in armtube material perspective.

The Background

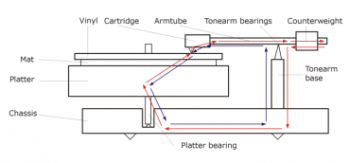

Figure 1 shows, why tonearm’s sound depends on armtube material (and why turntable sound quality depends on mat material).

Fig. 1. Acoustic vibration spreading through the sound system

Fig. 1. Acoustic vibration spreading through the sound system

Stylus, while moving in the vinyl’s groove, not only produces the musical signal, but also oscillates the cartridge itself. The oscillation (shown in red arrows) can be transferred through the armtube, partially reflect from the counterweight, and through the tonearm bearings, tonearm support, chassis, platter bearings, platter, mat and vinyl return back to the stylus. On the other hand, stylus causes vinyl plate vibrations (blue arrows), which, through the mat, platter, platter bearings, chassis, tonearm support, tonearm bearings and armtube, return to the stylus again.

The interference of these two acoustic vibrations can slightly impact the sound quality. Armtube material can suppress these parasitic accoustic vibrations (and of course, tonearm’s effective mass depends mainly on armtube material).

The Gear

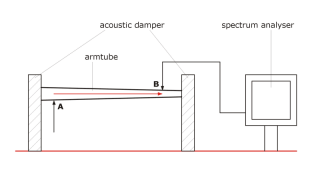

To carry on with the research, we built the device shown in Figure 2 (you can see its picture in the top-right of the article).

Fig. 2. Armtube testing device scheme

Fig. 2. Armtube testing device scheme

It consists of two acoustic dampers, holding the armtube; at the point A a broadband acoustic signal is fed; at the point B, it is registered using the broadband acoustic receiver and then passed to the spectrum analyzer.

The Wood

We acoustically tested following armtube materials:

- Western redcedar,

- Ebony Macassar,

- Cocobolo,

- Pernambucco,

- Pao Ferro,

- Panzerholtz (Tankwood)

- Zirocote

- Wenge.

- Teak

Also for comparison we carried the same test to Carbon fiber, Fiberglass and Aluminum arms.

The Result

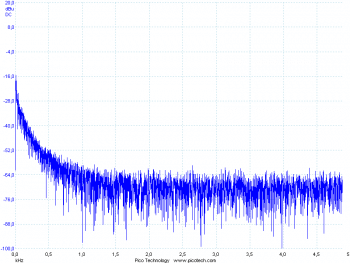

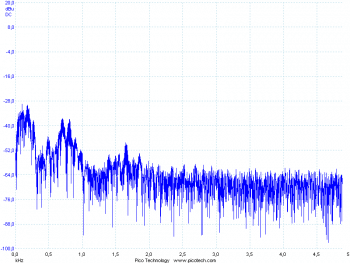

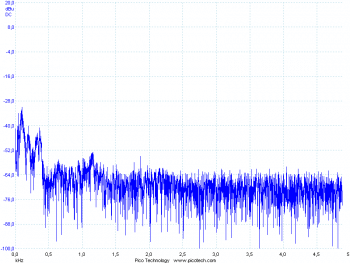

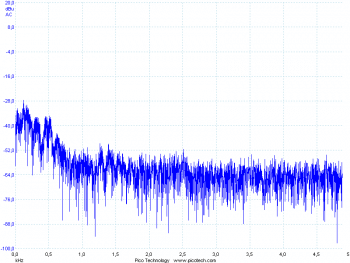

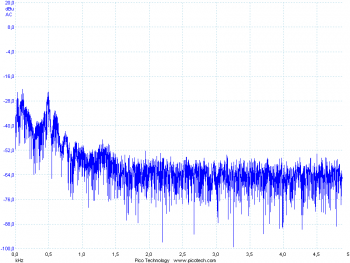

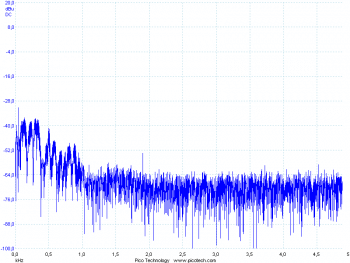

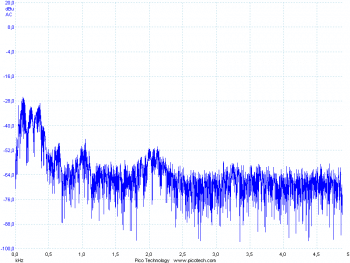

As you can see from the graphs on the right side of an article, woods with closest-to-perfect characteristics are Redcedar, Pernambucco and Panzerholz. They don’t have clearly expressed resonant frequencies, and their sound damping characteristics are close to exponential function.

Results of our test are basically same to some audiophile opinion, that tonearms with Redcedar and Pernambucco wands produce very clean, transparent and deep sound. Meanwhile, even if tests show Panzerholtz being nearly perfect material for the arm, audiophile opinions on it are different.

Tool for testing armtube sound properties Acoustic characteristics in Perfect conditions

Cocobolo (Dalbergia retusa) arm Acoustic characteristics of Cocobolo arm

Brazilwood (Caesalpinia echinata), also known as Acoustic characteristics of Pernambuco arm

Pernambuco, arm

Wenge (Millettia laurentii) arm Acoustic characteristics of Wenge arm

Zirocote (Cordia dodecandra) arm Acoustic characteristics of Zirocote arm

Teak (Tectona) arm Acoustic characteristics of Teak arm

Makassar ebony (Diospyros celebica) arm Acoustic characteristics of Makassar ebony arm

TONEARM MOMENT OF INERTIA

The main criteria for designing, producing and choosing to buy tonearm are often wiring (internal and external), connections, and effective mass and geometric dimensions of tonearm which is clearly very important. However, there are some other criteria, such as tonearm moment of inertia (It) and acoustic resonance characteristics, which are often left out while they should be considered as well.

It is the sum of cartridge moment of inertia (Ic) and counterweight moment of inertia (Iw).

It = Ic + I

Even with smallest LP twist or miscentering, It would affect VTA (Vertical Tracking Angle), SRA (Stylus Rake Angle) and VTF (Vertical Tracking Force) of tonearm. It influence on VTA, SRA and VTF causes distortions that are subjectively heard as detonation. The frequency of distortions varies from 0.5 Hz to 20 Hz and can be up to 0.5 %.

To reduce these distortions, usually damping systems are used. Both mechanical and magnetic damping systems are complicated and quite expensive. However we suggest reducing It, which is the main reason of distortions, first.

Moment of inertia depends on mass and square of distance formula.

Research shows that Iw can be reduced by increasing the mass of counterweight and pushing it towards the bearings. The mass of counterweight can not be highly increased because the bearings will get overloaded and that will cause friction problems. In order to minimize friction sapphire bearings with tungsten carbide points are used. These bearings rest sphere on sphere (both spheres having different radius). Clearance of bearings is not possible because it will cause azimuth and VTA errors and make additional distortions. For this reason constantly loaded bearings should be used.

Ic can be decreased by:

1) Reducing effective mass. Effective mass of tonearm can be reduced by changing the material of armtube. Tonearm should be matched with cartridge so that Tonearm Resonant Frequency is 10 +/- 2 Hz. Therefore, effective mass of tonearm must be within certain limits.

2) Reducing effective length of tonearm. Decreasing the length of tonearm to less than 9” increases tracking error distortions. On the other hand, if the length of tonearm is more than 12”, the distortions caused by It become more significant.

Statics of tonearm (static position) can be expressed by the following equations:

where

mc – cartridge weight,

mch – head shell weight,

mat – armtube weight,

lef – effective length,

lw – counterweight section length,

mw – counterweight weight,

mwh – counterweight holder weight.

Because Iw should be (and usually is) at least 10 times smaller than Ic, for approximate calculations we should examine only Ic:

where

mc – cartridge weight,

mef – effective mass,

lef – effective length,

Ic should be less than 20 000 g×cm2.

REED 3Q TONEARM WORKING PRINCIPLE

Laser-adjusted tonearm operation is based on a level principle and helps to determine when tonearm mounting surface is parallel to the headshell (cartridge mounting) surface.

When using laser-adjusted tonearm, it is possible to adjust VTA and azimuth very quickly, comfortably and precisely after changing LP with different thickness or switching cartridges.

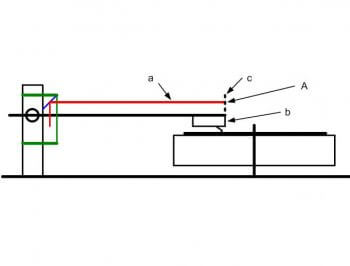

Laser beam a is adjusted so, that when it points to the point A on the scale c of the headshell b (Fig. 1, Fig. 2), the tonearm armwand is parallel to the tonearm mounting surface and a platter, i.e. VTA is adjusted to zero position.

Fig. 1. VTA adjustment using laser (scheme) Fig. 2. VTA adjustment using laser (photo)

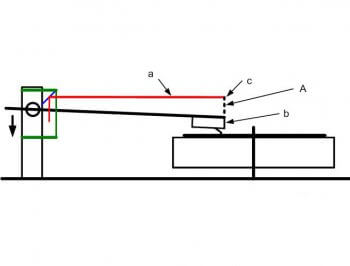

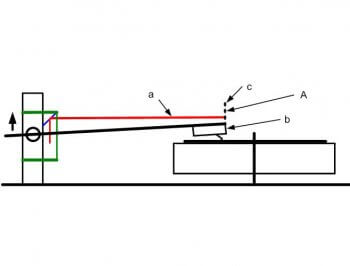

If laser beam points above the point A (Fig. 3), tonearm must be lowered until the beam appears at the point A. If laser beam points below the point A (Fig. 4), tonearm must be raised until the beam appears at the point A.

Fig. 3. VTA adjustment using laser – Fig. 4. VTA adjustment using laser -tonearm too low (scheme)

tonearm too high (scheme) tonearm too low (scheme)

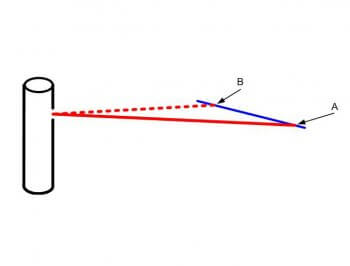

Headshell (cartridge mounting) plane is parallel to tonearm mounting/platter plane if, after turning the tonearm, laser beam a points to the point B, (Fig. 5, Fig. 6). That means azimuth is adjusted to zero position.

If laser beam does not appear in point B, azimuth must be adjusted accordingly.

Fig. 5. Azimuth adjustment using laser (scheme) Fig. 6. Azimuth adjustment using laser (photo)

OUR WORKSHOP

Here you can find a few pictures of our workshop, lab equipment and testing tools. And we have quite interesting ones here… For example, our Griffin turntable, used primarily for tonearm tests, features two stationary towers for tonearms and one spare place, where either tower for the third tonearm or motor can be mounted. Motor is mounted when we are carrying motor tests, i.e. validating motor speed etc.

We also built a device for tonearm armtube sound properties test. Everyone knows, or might guess, that wooden arm sounds better than one made of metal, but how to prove it? So, to check if wood is really better than a metal, also to compare wood with other materials (e.g. fiberglass) and different wood kinds itself, we made a quite simple yet interesting device. Its working principles will be described further in an article devoted to armtube material tests.

Griffin turntable, used for tonearm tests

Griffin turntable with three tonearms mounted

Tool for testing armtube sound properties

Making tonearm: armtube production