Helix Two MK3 Vacuum

The Helix Two Mk3 has endeared itself into the hearts of many audiophiles and music lovers around the world for the musicality, detail and emotional nature of the playback experience it delivers. Despite not offering a vacuum system, it has been frequently compared favourably in reviews to other turntables at higher pricing levels which feature vacuum. For many owners, the vacuum system may be deemed to be unnecessary. However, for those customers who demand a vacuum system for the benefits that it gives and desire to have that ‘ultimate’ specification of a Dohmann turntable, the Helix Two Mk3 Vacuum is a revelation. The vacuum system creates suction and turns itself off just as the stylus touches the grooves. There’s no pump action during replay at all and even if the system experienced a loss of suction which required the pump to activate, it is designed in a way that its operation is silent and decoupled from any aspect of the system that may affect the sonic performance. Furthermore, the ‘virtual o-ring’ technology results in absolutely no influence of platter inertia whatsoever. This level of performance is simply unprecedented.

Please read the information on the Helix Two Mk3 to better appreciate the foundations for this statement turntable by internationally acclaimed analogue designer Mark Dohmann and his team.

What does a vacuum hold-down system do?

A vacuum turntable uses a gentle suction beneath the record to draw the vinyl firmly and uniformly onto the platter surface. For this to work, the platter must have a special design: an air channel or pathway and a sealing mat or lip around the edge that allows the vacuum to create a seal under the record. Once the vacuum is engaged, the vinyl becomes effectively part of the platter — fully “coupled” and flat, eliminating air gaps and ensuring full-surface contact. This pressure is evenly spread across the whole disc, not just at the label/spindle area (as with a clamp) or edge (as with some stabiliser rings). Aside from presenting a flat vinyl record, the vinyl and the platter present as one ‘effective mass’, which has sonic benefits.

What are the sonic benefits of a well-designed vacuum hold-down system?

Eliminates warps and air gaps

A vacuum hold-down system forcibly flattens the record against the platter, whether the vinyl is slightly warped, has uneven pressing or simply isn’t perfectly flat. This ensures the stylus rides the grooves with consistent geometry. This can help avoid groove mis-tracking, distortion, or pitch instability that might otherwise result from warps or uneven contact. Because the entire surface is in intimate contact, you avoid “air pockets” under the record that might introduce resonance or micro-flutter.

Better stylus tracking and groove contact

With the record held perfectly flat and flush, the stylus can maintain consistent contact with the groove walls and floor, which improves tracking accuracy. This helps especially with delicate groove passages, subtle dynamics, and complex recording mixes, where even slight variations in contact can smear or blur detail. Also, because vacuum hold-down distributes force over the entire disc, it avoids some of the potential downsides of clamps (which only press at center) or weights (which increase inertia but may not flatten warped records completely).

Reduces resonance, vibration & feedback loops

Analog playback is highly sensitive: as the stylus tracks the groove, it generates tiny vibrations. Those vibrations can travel from the vinyl to the platter, bearing, and even into the tonearm or plinth — potentially feeding back into the stylus and muddying detail. By rigidly coupling the vinyl to the platter, the vacuum system reduces the chances for micro-movements and resonance, minimising energy interplay between the stylus and platter. This means fewer distortions, less “smearing,” and a more stable, accurate reproduction of the groove’s fine details.

More consistent speed & stability (less wow/flutter noise)

Once the record is tightly coupled to the platter, there’s less likelihood of slippage or micro-variations in rotation, both of which can cause wow and flutter (subtle pitch fluctuations) or timing instability. A vacuum system results in a minimal increase in rotational inertia compared to heavy weights, meaning less strain on the motor and platter bearing, yet you gain improved rotational stability.

Increase in sonic clarity, detail and accuracy

The overall improvement of superior stylus contact, reduced micro-vibrations and the elimination of warps/air gaps is less resonance and fewer mechanical anomalies. This allows the stylus to convert the groove geometry into an electrical signal more accurately. Discerning listeners report fewer distortions or colorations, which often improves midrange purity and clarity of vocals and instruments. Tighter bass, greater low frequency clarity, improved transient impact (drums, percussion), more image stability and better overall fidelity.

Why have we delayed offering our customers this feature?

Mark Dohmann has been building turntables since 1982 and has a lot of experience designing and building vacuum hold-down systems. When Dohmann Audio started the Helix project in 2013, Mark designed the Helix One and Two from the beginning with the vision to incorporate a vacuum system in the future. The architecture of the Helix platform has always had accommodations for a vacuum system and we have been quietly working away on a vacuum hold-down system with the intention of introducing it when we felt that it would represent value to our customers.

As our research & development progressed in the ensuing years, we were able to bring the operating noise floor of our turntables to unprecedented low levels. Due to advances in materials science, engineering & manufacturing technologies and test equipment capability, the Mk3 generation of turntables in particular are operating with noise floors that would have been considered impossible a few years ago.

This rapid technological development posed a problem for incorporating a vacuum hold-down system. Traditional vacuum systems are relatively unsophisticated, contributing noise and various sonic artefacts to the playback performance. They can also be unreliable, require onerous maintenance and in high resolving hi-fi systems, can be heard operating during music playback. The lower we dropped our operating noise floor, the harder it became to incorporate a vacuum system that did not interfere with the playback performance and did not suffer from the traditional vacuum system issues.

We realised that to satisfy those customers who desired a vacuum hold-down system in our turntables, we had to go back to the drawing board and design something completely different to what has been used in the past. Mark consulted with the industrial manufacturing industry and researched the most advanced vacuum systems used in this sector. He found a new way of applying these technologies to the ecosystem of a turntable. The result is an advanced Rotary Feedthrough Technology using ‘shaped oil’ virtual o’ring seal technology to protect the rotating shaft and platter from air leaks. It has taken us a few years to create a version of this technology that can be used in audio reproduction but the wait has been worth it.

The Dohmann vacuum hold-down technology is revolutionary in that it has never appeared in turntable applications before and it is so far advanced from existing vacuum designs that we can finally introduce it as an option to our customers. Finally, a vacuum system which is completely operationally sonically INVISIBLE and highly reliable, resulting in a positive ownership experience with elevated performance benefits.

Read about the vacuum system in greater detail here.

Upgradability

The Helix Two platform is fully upgradable. Mk1 and Mk2 generation turntables are upgradable to Mk3 and the Mk3 is upgradable to vacuum specification. This protects our customer’s investment and avoids significant depreciation often experienced when a new model is released. The Helix platform was designed from the beginning to be upgradable as new technologies are discovered, tested and integrated.

Features

- Dohmann vacuum hold-down system featuring Rotary Feedthrough Technology

- Facility for one tonearm

- Custom designed Swiss-manufactured motor

- Push button Speed Adjust

- Separate external advanced DC power supply

- Micro Signal Architecture© (MSA)

- Negative Stiffness Mechanism Vibration Isolation (NSM)

- Mechanical Crossover Technology (MCT)

- Tri-Modal Platter system (TMP)

- Edge Damping Ring (EDR)

- Tone arm Damping System (TDS)

- Resonance Tuned Suspension (RTS)

- Diamond Like Coating Amorphous Material Bearing Friction Modifier (DLC)

- High Torque Adjustable Drive (HTAD)

- RSA resonance control technology

- Advanced Composite Armboard (ACA) using custom ballistics grade energy absorbing technology

- Record Clamp with RSA resonance control technology

Finishes

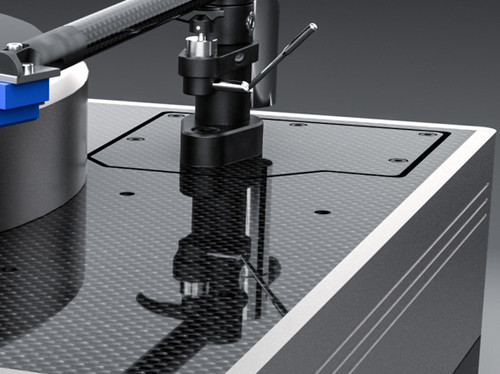

All Helix Two Mk3 Vacuum turntables come with a bespoke carbon fibre top plate and are available in the following Finishes. For more information and images, please refer to the section ‘Finishes’ in the Technology section.

- Black

- Sterling Silver

- Graphite

- Titanium

A two chassis system

The Helix Two Mk3 Vacuum turntable system consists of the main turntable chassis and a second vacuum system chassis (box). Please note that when upgrading from a Helix Two Mk3 to a Helix Two Mk3 Vacuum, the standard Helix Two’s separate power supply chassis is replaced by the Vacuum Chassis (Box) – a new power supply is included within the Vacuum Chassis. The faceplate of the Vacuum box can be ordered in a black finish or in the chosen finish of the turntable so it matches the turntable.

Specifications

| Operation | Operated by two push buttons on the table top plate for speed selection/on/off. |

|---|---|

| Speed Control | Speed is constantly calibrated over 130,000 times per second to deliver precise 33.33 or 45.15 rpm (factory default). Default factory set speeds are 33 RPM and 45 RPM. Please note that 78 RPM and other custom speeds are available by request. Simple user-adjustable speed control is accessible via two intuitive push buttons on the rear of the main chassis. |

| Drive System | Fully integrated Swiss-manufactured high torque motor (de-coupled). Dual-belt platter drive designed to reduce static electricity and vibrations. |

| Tonearm Facilities | One armboard to facilitate the mounting a tonearm up to 12” (305mm). |

| Armboards | All Helix One Mk3 turntables come with two Mk3 Advanced Composite Armboards. The armboards are removable and allow simple interchange and calibration. |

| Power Options | 110-120 VAC, 50/60Hz 2A 220/240 VAC, 50/60 Hz 1A |

| Dimensions | Turntable without clamp or tonearm: 480mm (W) x 400mm (D) x 200mm (H) 18.9 inches (W) x 15.8 inches (D) x 7.9 inches (H) Dimensions of vacuum system box: 432mm (W) x 420mm (D) x 150mm (H) 17 inches (W) x 16.5 inches (D) x 5.9 inches (H) |

| Weight | Turntable: 38kg (84 pounds) Vacuum Box: 14kg (31 pounds) Total weight: 52 kg (115 pounds) |